Problem

Growing value-added plants like tomatoes, chillies etc.. indoors requires significant knowledge of the growth, intensive human attention & effort for maintenance. Exact requirements of water & nutrients for plant growth is not known during the lifecycle of the crop. Portability is a major constraint in the indoor gardening system and most system occupies considerable space.

User

Indoor practitioners who are ambiguous about plant nutrition feed and working city occupants who travel frequently.

My Role

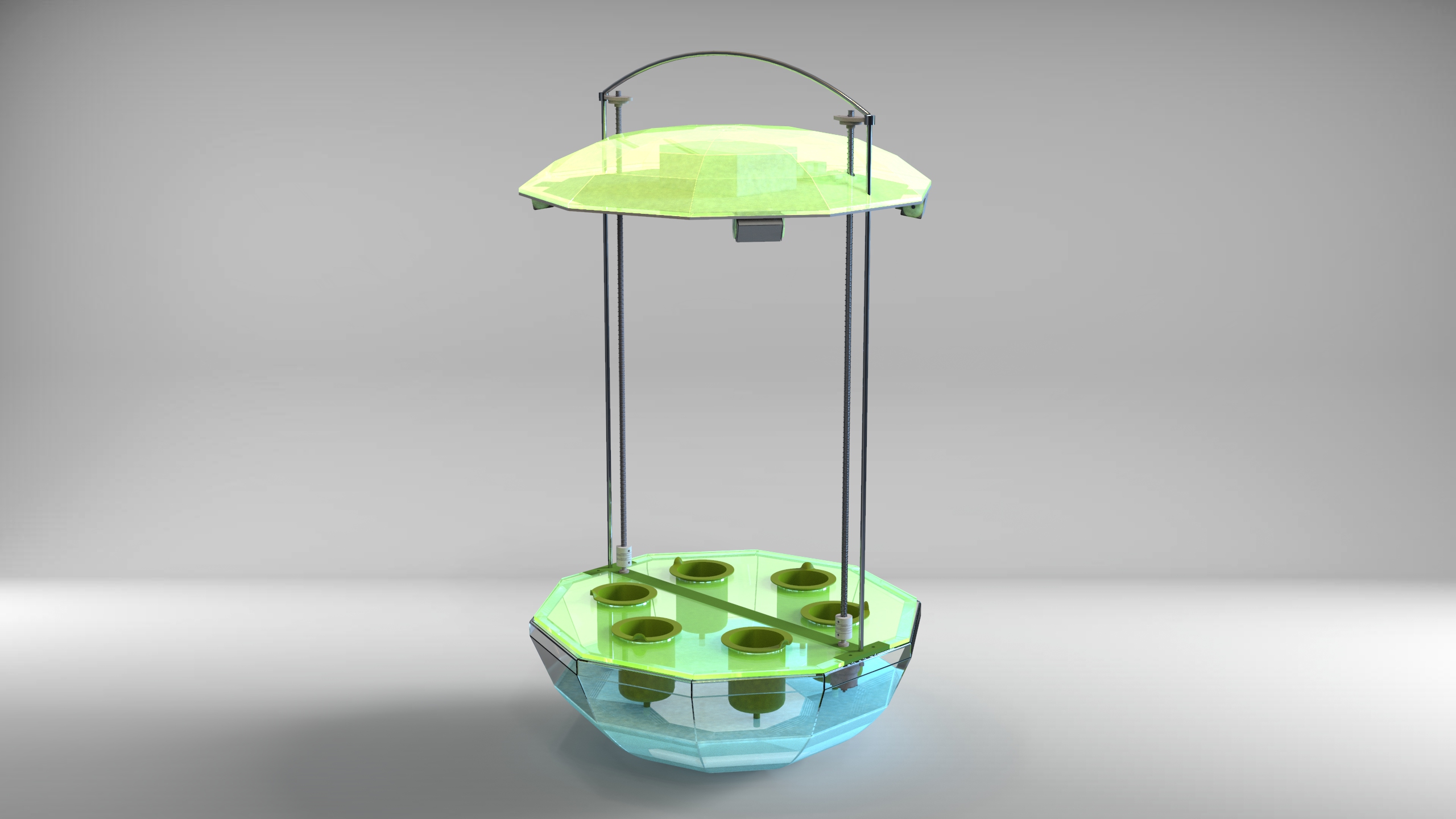

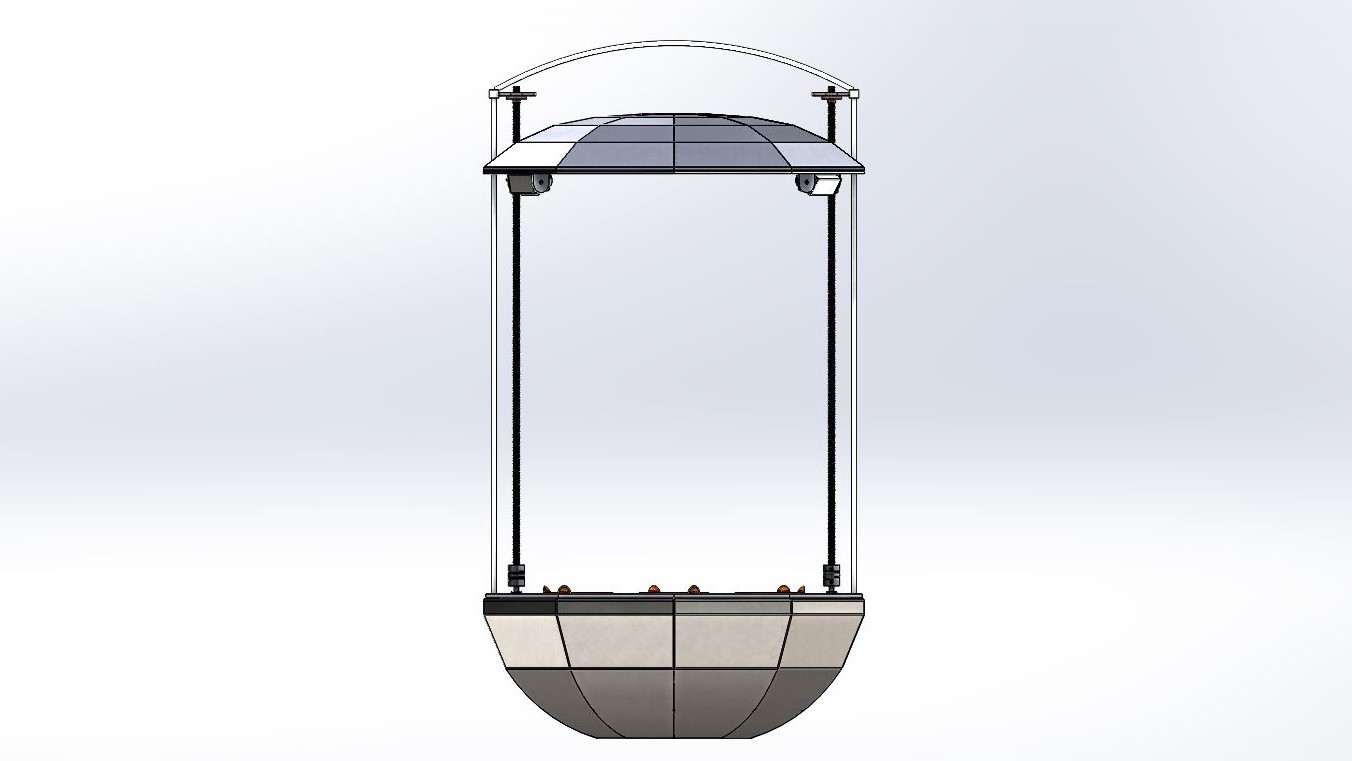

My role is to design a Minimum Usable Prototype which could be placed inside a home which is portable and not disturbing the daily lifestyle to prove its own values. The device uses a special lamp to simulate sunlight to the plants. The idea was to make a device that can be used to showcase the value and functionalities.

Design Process

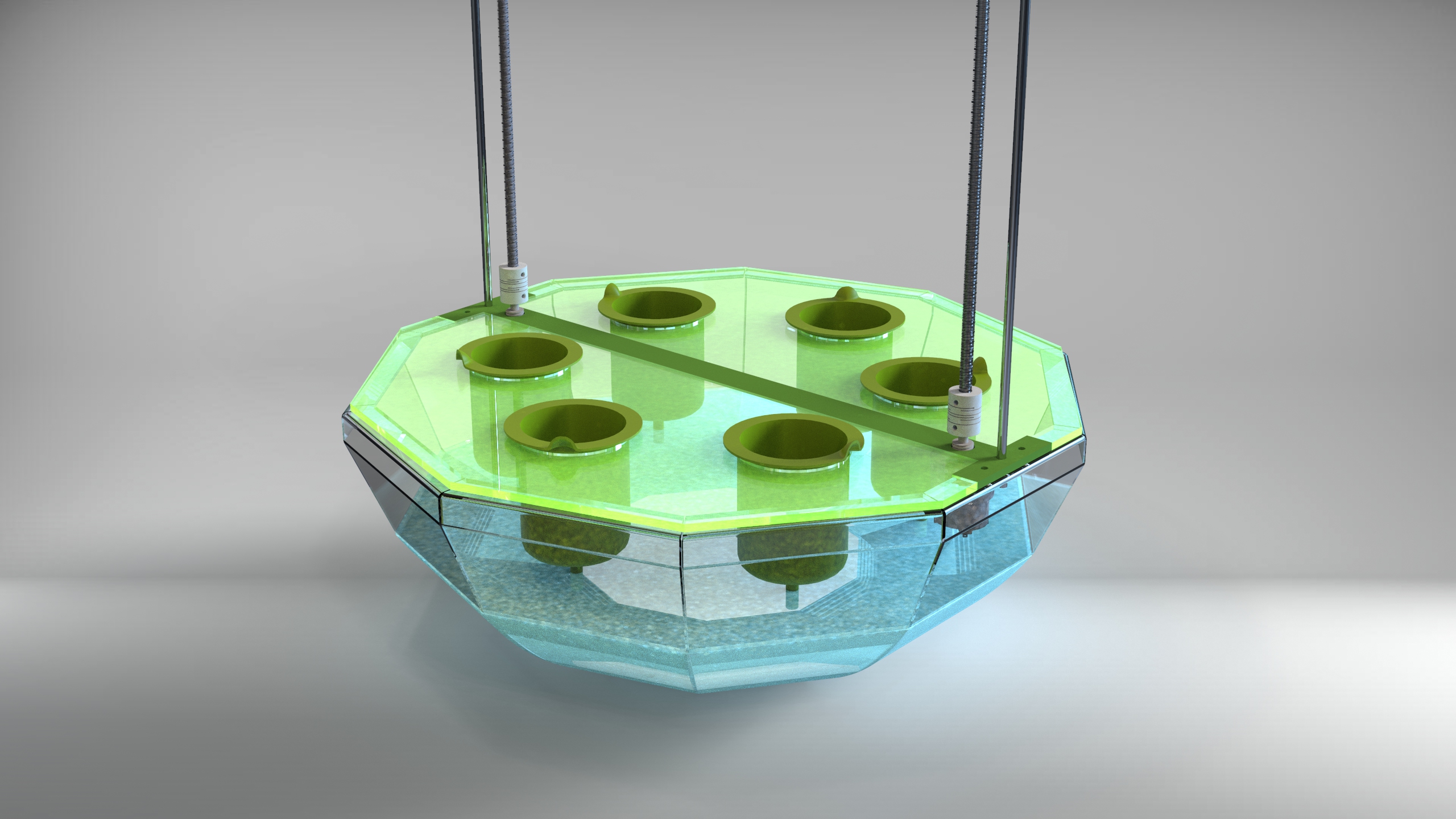

Each and every requirement were accomplished in the design process by incorporating sufficient parameters. Since it is a prototype the manufacturability was considered crucial. Various manufacturing processes such as 3D Printing, injection moulding, Sheet metal fabrication, acrylic fabrication etc. Sheet metal and acrylic fabrication were more efficient and cost-effective comparatively. CMF selection played a very important role to make the device suitable for showcasing the functionality. Acrylic was chosen over sheet metal due to its transparency which will enable people to see the design of the seed pods inside the bowl. The seed pods alone were designed to be 3D printed. Even the pod design was optimized to be 3D printed by splitting it into 3 parts to reduce print time and material wastage. The pod was designed perfectly to hold the soil and also to enable capillary action through the fibre used in the bottom. The pod can be accessed easily by the provision to hold it. The height of the light dome in the top was to be actuated but choosing the mechanism was a challenge. After exploration of many actuators, lead screw mechanism was chosen for the prototype due to its low cost and high torque specification. The topology of the electronic components such as microprocessors, power circuits and motor drivers were a great challenge due to its effect on the centre of gravity. Also fixing of the actuation system was a difficulty which taught me a lot of things. The whole device was designed and fabricated successfully.